Project Elements

Elements of some current and recent projects...

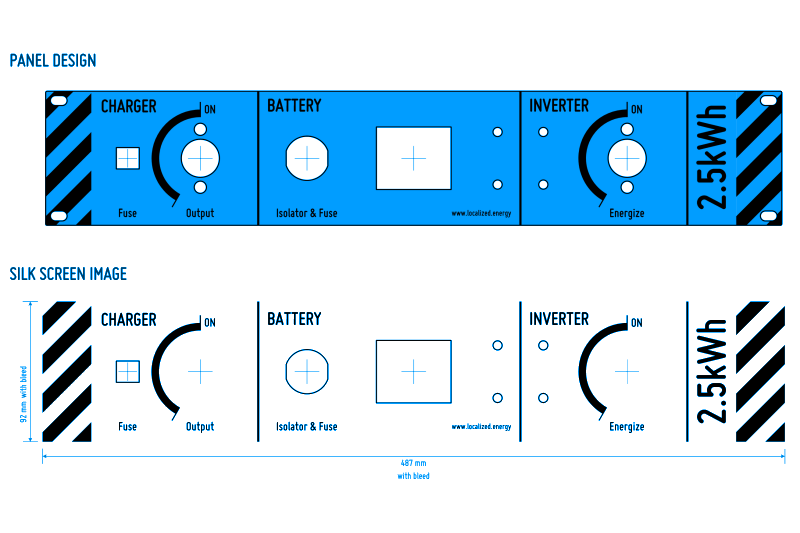

To protect our operations we are designing our own rack-mounted extended-endurance UPS systems (yes, more than one) to run servers, communications and security devices during extended power outages.

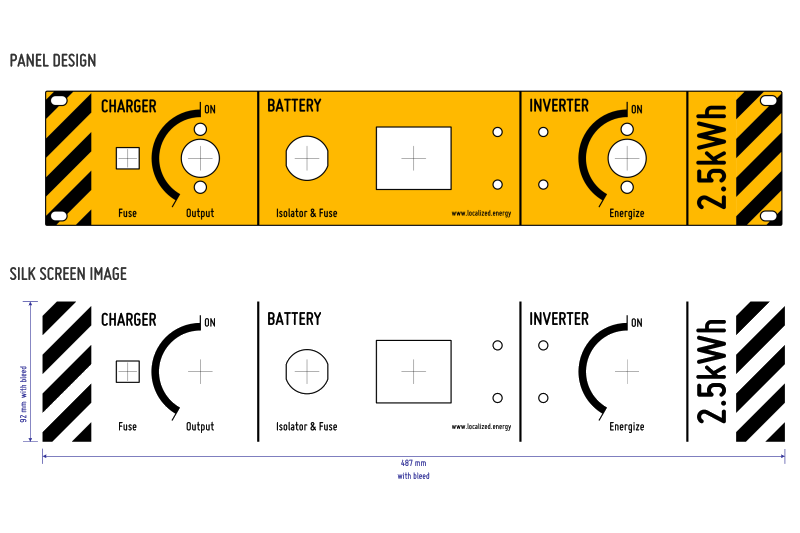

Custom electrical installations need custom control panels. In this case we are using a 1.5mm mild steel panel, laser-cut to our design and powder coated in bumble bee yellow. Control markings, vertical segment lines, text labels and diagonal side hazard bars are over-printed in black and then baked on for a durable finish.

Consumer Unit with Custom User Interface.

For rapid prototyping we might use in-house 3D printed plastics, as here with the custom keypad designed to fit within a consumer unit's standard aperture.

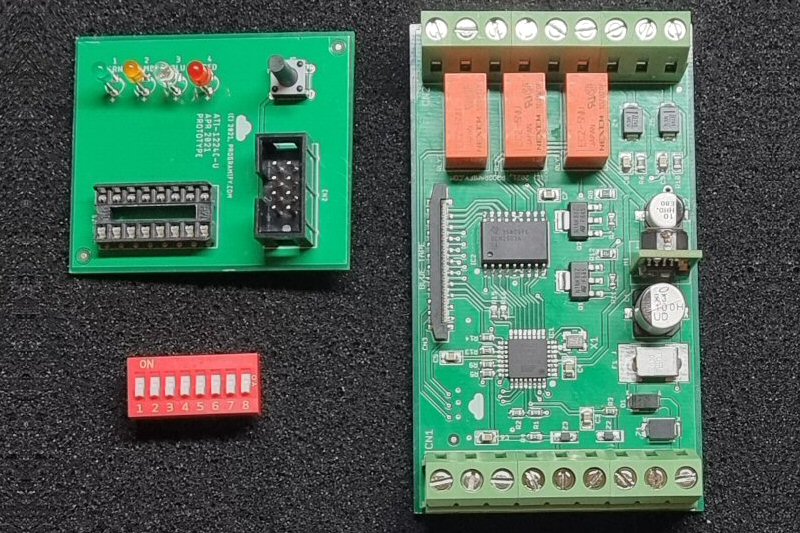

The keypad was built from the ground up, even the keycaps were silk-screen printed and lacquered. A custom keypad also needs a custom keypad decoder. As you might expect we designed and built our own embedded solution which also takes care of debouncing the tactile keys and translating hardware scan codes to ASCII characters.

We're happy to work with diverse materials such as PLA, ABS, fibre reinforced plastics, steel and aluminium.

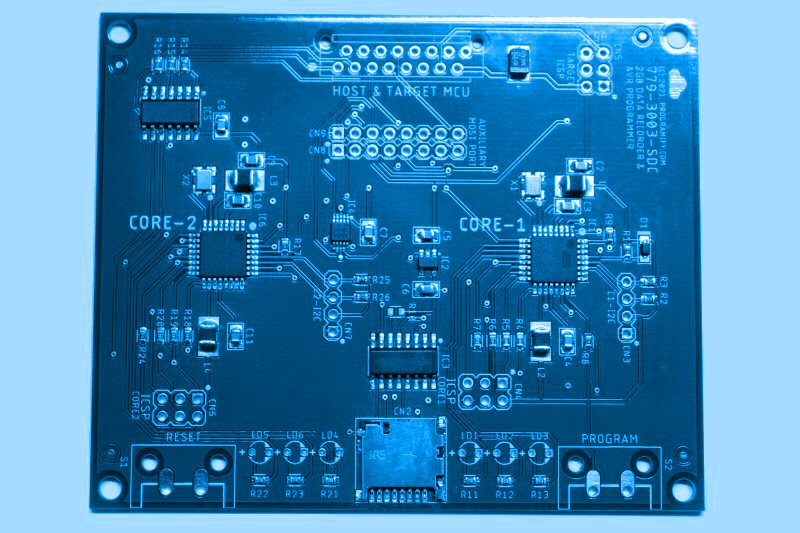

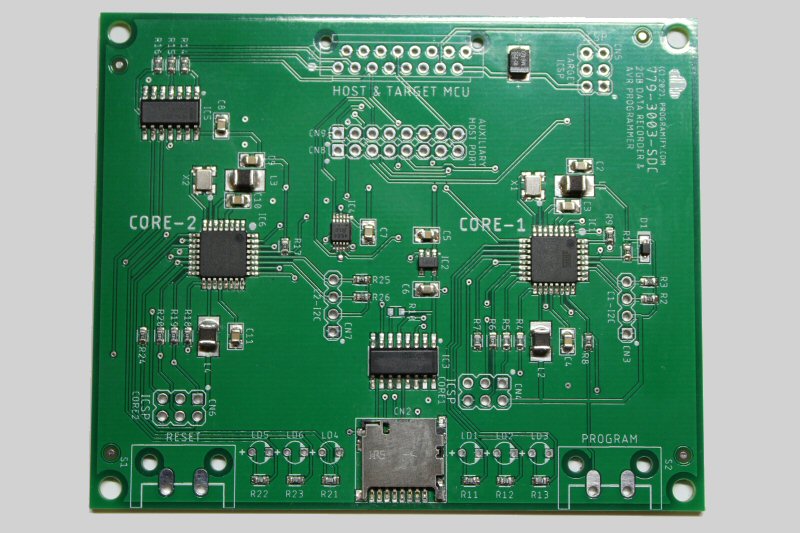

Our prototype design included a 2GB micro-SD card slot operated from one processor (Core-1) while the AVR programmer was operated exclusively by a second processor (Core-2).

Two processors were neccessary to greatly simplify the firmware. The target processor would be unaware of the module's programming capability, and would have just seen it as a data logging service. Instead we can keep firmware versions and updates on the SD Card and re-flash the host with the press of a single button.

Ideal for in-the-field firmware upgrades. Just place a new SD card in the slot and press the Upgrade button. Too easy.

Signalling with Fault Detection

All alarm systems have the same problem: How do you know your trigger sensors are still connected and working 24/7?

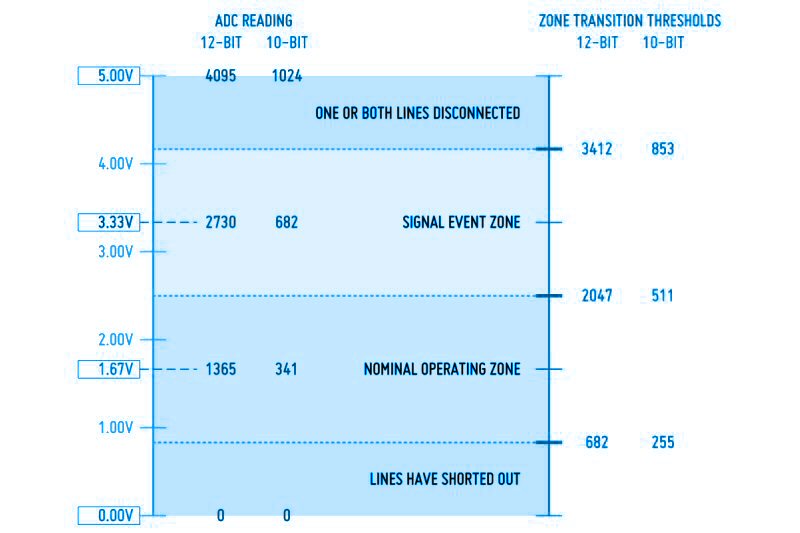

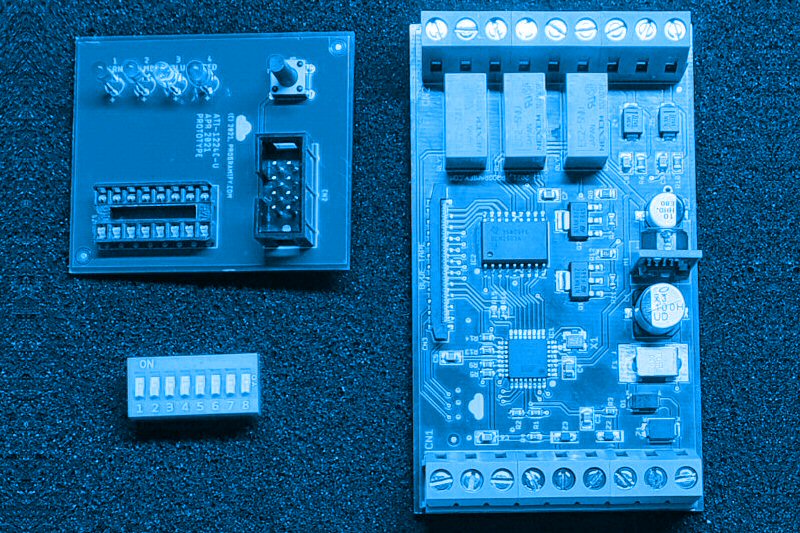

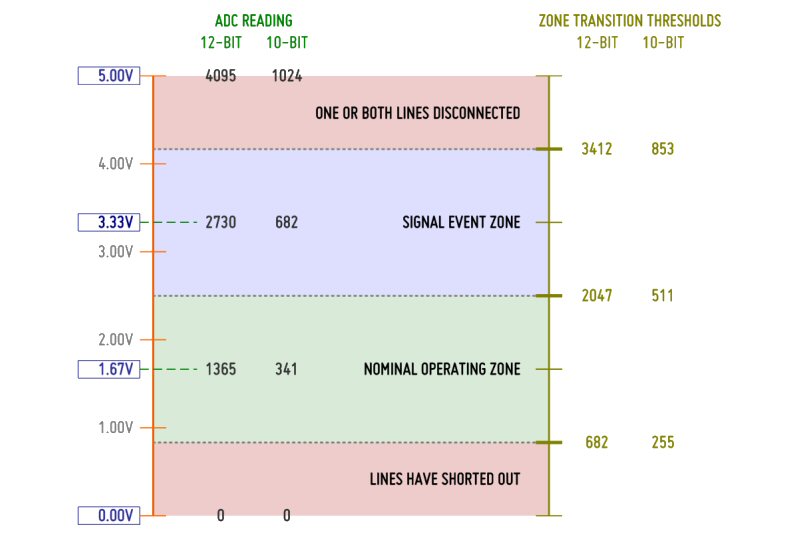

We use our own design of end-of-line resistor pairs to differentiate between line shorts and line disconnects, they also allow the remote sensor to indicate all is well or if they have triggered.

Using a low voltage analog DC signal running in grounded Cat-6 STP cable, the line voltage is measured by timing software to determine the line state. Electronics on the receiving end also filters out residual RF noise and blocks electrostatic discharges.

Reliably detecting when a trigger sensor has been activated is a little more complicated than a doorbell.

The complexity arises from three requirements: The flexibility to be configured and installed into a variety of different sites. Second, any trigger event must be just that, a real trigger event and not a glitch arising from a nearby lightning strike or radio interference. Third, where possible, faults should be reported down the line when they happen 24/7, and not just when the unit is next manually checked.

The embedded firmware helps minimize that hardware complexity whilst giving maximum flexibility to the overall application.

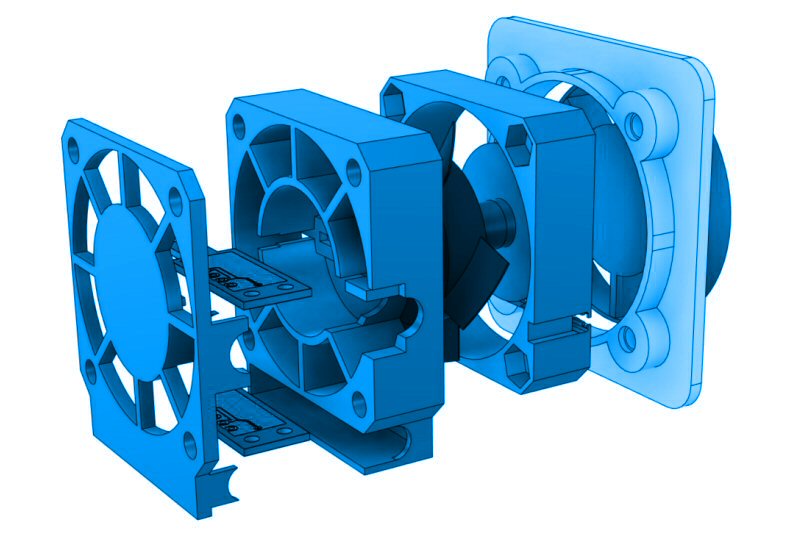

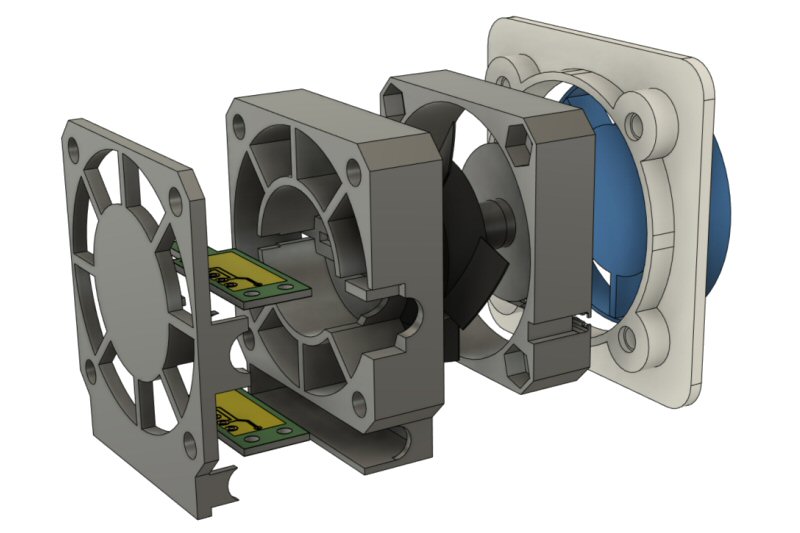

3D printing at its best allows you to design a piece of plastic that performs two or more functions.

While building a medium sized enclosure we needed to fit two small fans: one intake (blue) and one exhaust (red). We designed the outer bezel to give a clean finish to the outside of the enclosure. Inside, the housing was aligned with the fan's four mounting screw holes to allow easy assembly. On the inner most surface we built in a temperature sensor designed to sit exactly within the airflow of the fan.

We found early on that minimizing disription to the airflow is key to minimizing the overall noise of the assembly.